Timber Garden Sheds Australia

March 2024

We try to NOT build any log cabins during the hotter times of the year, we use the time after the Festive Season for on-line work, refining our cabin offer for the next year, work on our websites, maintain our fleet and so on. We managed to make some progress on our TINY HOUSE "Freedom28" but the wet and humid conditions made for slow progress. When the weather started to cool down we immediately started to work on the back log of cabin builds. First up was a "SAM10" that weirdly enough is REALLY used as just a garden shed!

Existing concrete slab

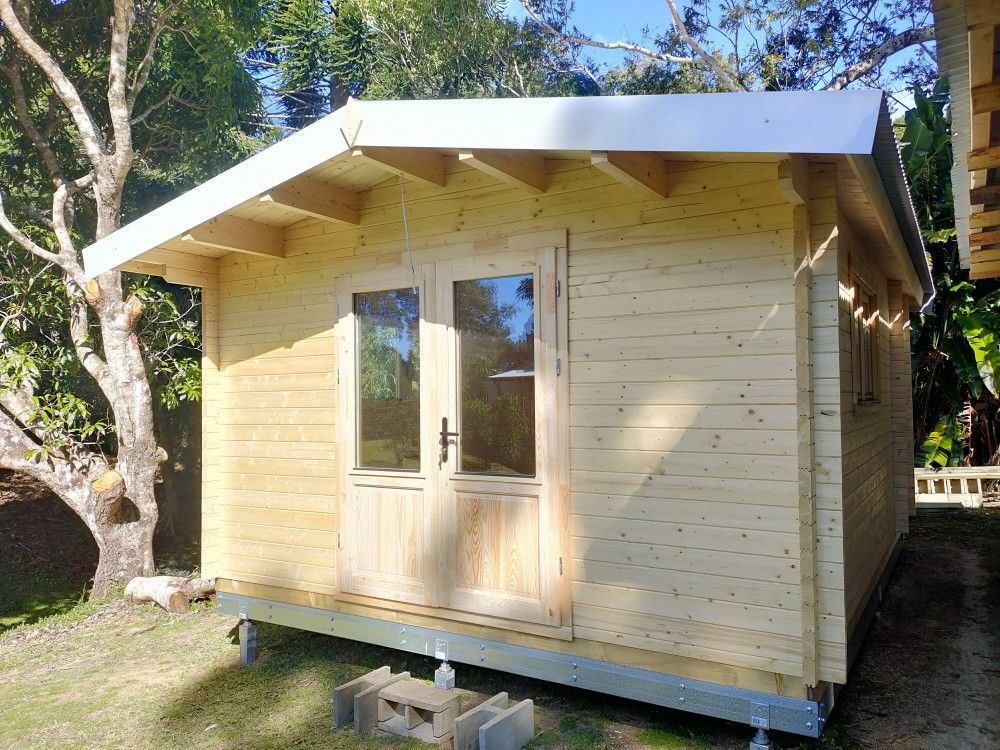

Joyce and David chose a location very close to their existing house. There was a nice pebble concrete slab, however, it sloped away from the house (as it should for water run off). So firstly the treated pine base frame that comes with the cabin needed to be pre-assembled and leveled.

The easiest way to level shed base frames on concrete slabs is to firstly raise the lowest corners. Next, hardwood lengths were positioned underneath the base frame by sliding them into spots were all base frame timbers had contact with the hardwood supports. Once that was achieved, the treated pine joists were screwed into the hardwood supports.

The pressure was on....

Due to frequently wet weather we had to delay this build on THREE previous occasions already. The rain was again threatening so we took full advantage of having four guys on site. Everyone worked as fast as we could, and when the weather turned bad early afternoon, we had the cabin dried in via the tongue-and-groove roof boards, plus we placed a tarp on top just to make sure the cabin stayed as dry as possible.

Normally, the particle board flooring would have been installed before the walls went up, to enable our crew to place ladders on it. The pending rain dictated leaving the particle board flooring out and concentrating on getting the roof boards installed.

The schedule was tight - but we managed!

Building (too?) close to the house...

Having the cabin as close to the main house is often the ideal solution, this avoids getting wet when going to the cabin on rain days, it also provides protection during storms.

However, sometimes, despite measuring as accurately as possible things don't quite work out. Here a down pipe running off the gutters of the main house proved to be a challenge. To keep building we partly dismantled the existing down pipe and installed a temporary plastic water tube to avoid too much water splattering.

A few days after this build was finished both the roof boards and the corrugated iron sheeting was cut to exact size enabling the re-assembly of the original down pipe.

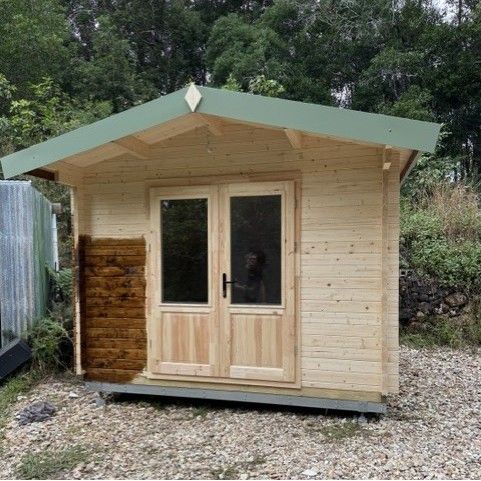

Another "SAM10" cabin finished!

After the rains finally stopped, we went back to site to do all "finishing touches" like installation of the doors incl. hinge fine adjustments, properly screwing down the roof ridge capping (only secured temporarily when the skies opened up a few days before), installation of door locks, and oiling an attaching the diamond shaped top gable end pieces.

We take great pride in the 100% completion of all cabins we install! AND - we clean up after ourselves, leaving no rubbish behind, sweeping the cabin interior and so on - we simply LOVE log cabins!

LIKE IT? SHARE IT!