Timber Garden Sheds Australia

July 2025

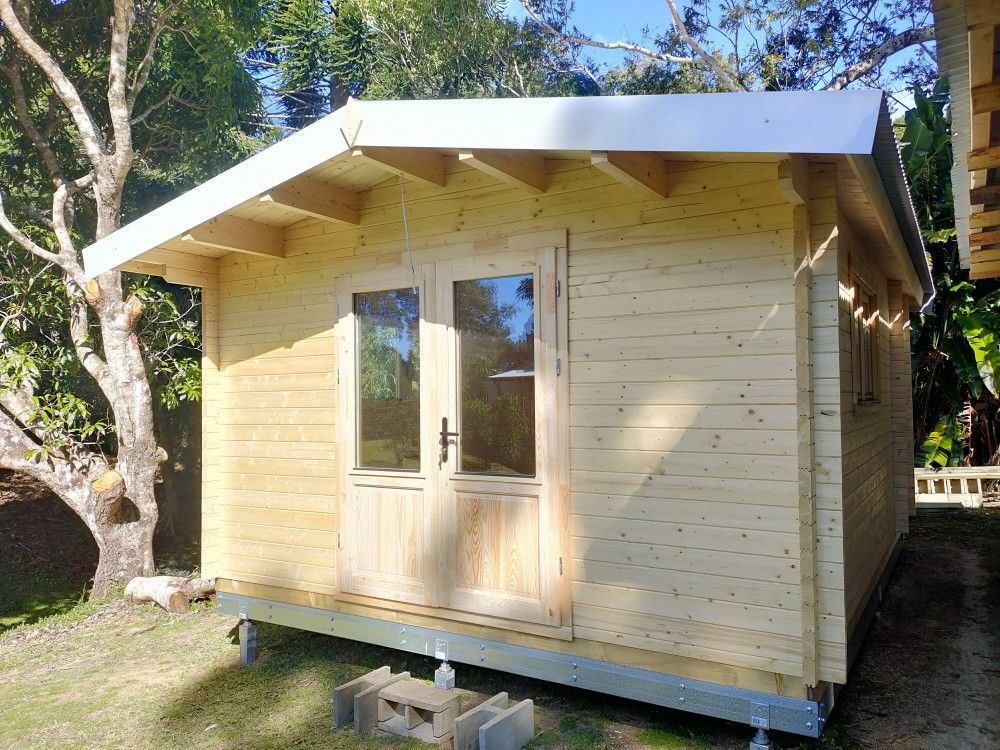

The variety of end uses of our cabins is amazing... In this case Linda needed a professional space for her home business. This space needed to look great, feel welcoming to clients, needed to be waterproof and well insulated as well as long lasting and structurally sound - the perfect description for our solid timber log cabins! The image above shows the finished cabin as at August 2025, boasting a top-notch paint job.

Foundations

This build site was located close to the centre of Fernvale. This meant accommodation and other facilities were close by, making logistics easier.

The cabin was placed facing the main road, next to the main residence. The site was pretty much level, with easy access all around.

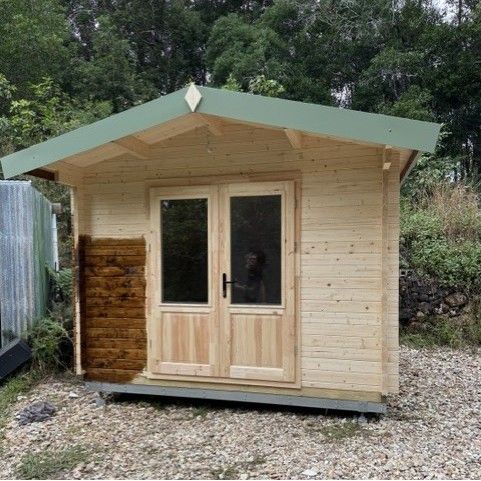

If you noticed that the images on the left look "dull" - you are right. The weather on the first day of this build was overcast, with the occasional light drizzle. We had to closely watch this as leaving power tools out in the rain is never a good idea.

But overall we made excellent progress - largely due to our great building team we had on site. Three guys make for quick work.

Second Day - still rain threatening

We tried to get this build done as quickly as we could - leaving not much time for chats and photos.... The images on the right are "fast forward" from the first row of images above.

The door architrave (but not the doors themselves) as well as the windows need to be installed as the walls go up. They CAN also be installed after all walls are finished, but this means much more work and fiddling around. The window that comes with the cabin can only be installed in the centre of any of the three walls, additional windows are available (please check with us) and can then be installed anywhere you like, but must be at least 300mm away from a log wall corner.

Lighting Cables

Our unique log thickness of 50mm (instead of only 44 or even 28mm) allows our factory to pre-drill electrical holes through the logs. This enables our local electricians to neatly install power points, light switches etc without using unsightly conduits and the like. Lighting cables must be installed BEFORE the roof sheets. It is close to impossible to get an electrician on site at exactly the right time, especially in remote locations.

We therefore run lighting cables from the switch at the entrance to all lighting outlets - one for the front door overhang (the cable show on the image on the right) and one or two outlets inside the cabin). We also pre drill cable holes through the treated pine base frame and insert a plastic tongue that extends at the bottom, so the sparky knows where we provided access for his cables.

You can spot the yellow plastic tongue sticking out underneath the cabin on the image on the right.

Another SAM10 done

We are always happy when the roof sheets are installed - as of that point forward the cabin is close to being fully "dried in". Barge and ridge capping make the cabin 100% waterproof.

The diamond shaped timber pieces you spot at the very top where the barge capping joins are for cosmetic purposes only.

The front doors can be tricky to adjust while the timber of the cabin has not settled yet. Timber logs move and "shrink" over the first few months after the installation, and also sometimes tilt a little. This is totally normal for a naturally grown building material, and just means that doors might need to be readjusted via the hinges.

LIKE IT? SHARE IT!