Timber Garden Sheds Australia

May 2024

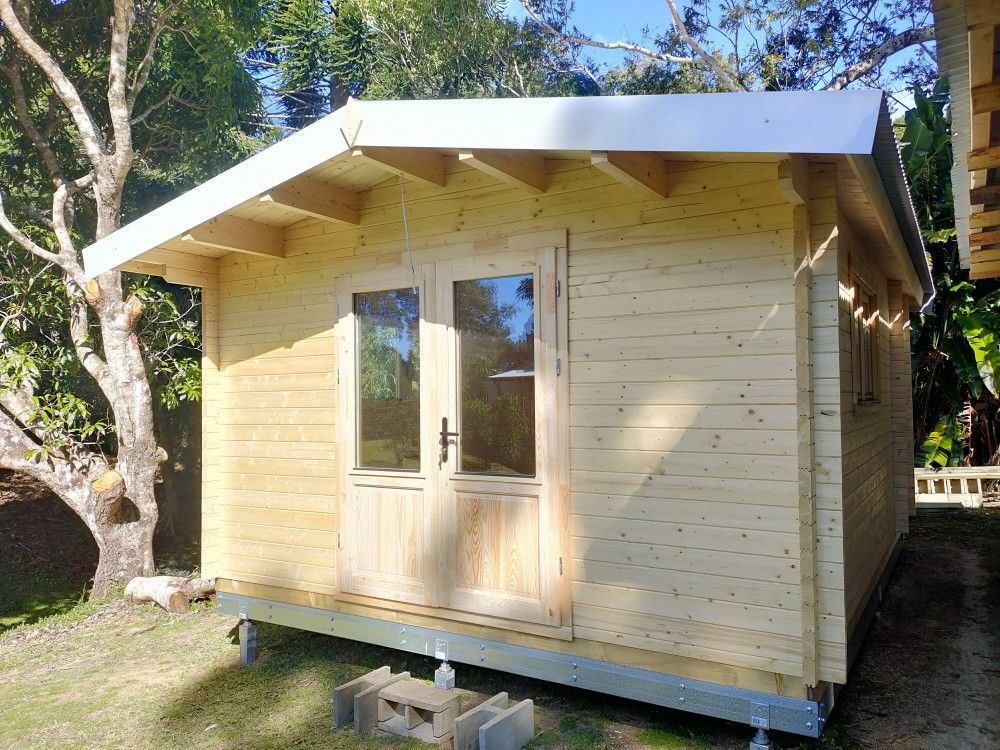

We managed to do this build in just two days, after the usual deliveries of material and the cabin a few days before. Being well organized before means that everything goes smoothly once the construction starts. There are a fair few items that are not included with the cabin pallet packed overseas, as these items are cheaper sourced here downunder, as well as being more suitable to the harsh Australian climate.

Ground Preparations

Another steel base foundation, ideal for log cabin garden sheds. The site was level already, Sunny and Matt had the lawn removed. We than placed black builders plastic on top of the soil, and topped this with a layer of gravel. This makes sure that NOTHING will grow back underneath the cabin, and also provided us with a clean surface to work on.

The importance of starting with the best possible foundation is often underestimated. Whilst placing your new cabin on pavers for example work s well in the short term, it still means that over many years rising damp will cause various issues. Yes, the cabin sits on top of a treated pine base frame that will help keeping your cabin off the ground, but raising your cabin off the ground is a much better solution.

Steel and Treated Pine Base Frames

Once the outer steel frame is assembled and the adjustable stumps concreted in, the cross purlins are installed. They are attached via general purpose angle brackets and M12 purlin bolts, very secure and strong.

The treated pine base frame is laid across the steel base, and attached also via a number of angle brackets.

On top of this the first row of logs is positioned, and electrical holes are drilled through the base frame using the existing pre-drilled electrical holes in the logs as a guide.

All our cabins come with a total of EIGHT pre-drilled electrical holes drilled though the centre of the logs (two in each corner of your cabin), they are not visible from either the inside or the outside.

Walls up

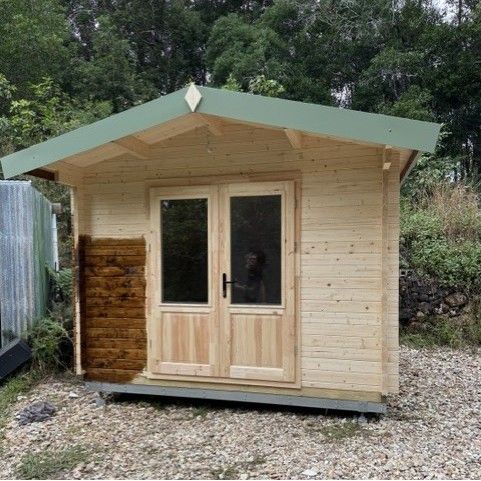

After building so many of these beautiful timber garden sheds in various regions of Australia we have the procedure down-pad! Everyone knows what needs doing, and we are extremely proud of our phantastic construction team.

However, this can also be done be anyone with handy experience! On occasions where the build site is far away from Brisbane and the Gold Coast, we work together with either you, the new owner of the cabin, and/or someone you organise to help. Ideally, three people are needed for assembling log cabin garden sheds, but it can also be done by two. Many hands make light work!

Change of plan...

Sunny and Matt decided to turn their SAM10 log cabin into a play room for their son instead of an office. Kids rule!

We took exactly two full days to complete this build to perfection. Additional works that still need to be done once we leave the site are electrical connection (power in as well as lights and power points), flooring (to go on top of the particle board flooring we installed) and painting or oiling of all log surfaces - especially important on the outside of course.

This entry was created on 1 May 2024. We currently have ONE only "SAM10" still in stock, more will be landing early June.

LIKE IT? SHARE IT!